Illinois-based biotech company Hydrosome Labs is tapping the use of ultrafine water bubbles featuring "diameters smaller than a bacterial cell" to double precision fermentation yields and decrease production time by up to 25%.

In effect, the company argues it can make beauty and personal care ingredients that are more affordable, effective (such as skin care materials with improved nutrient uptake) and sustainable than conventionally produced materials.

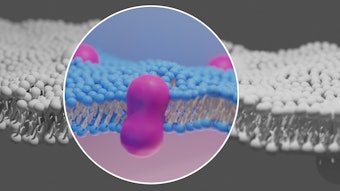

According to Hydrosome Labs, ultrafine bubbles "enhance the delivery of active ingredients," leading to better resulting materials while cutting down on the need for penetrating agents and other extraneous materials in the production process.

Specifically, these bubbles "increase cellular growth, overall biomass and target molecule titers," per the company. "This leads to more efficient operational processes that minimize resource consumption and produce more affordable products for consumers."

"It’s truly exciting to see how easily the ultrafine bubbles produced by Hydrosome’s technology integrated into our pilot scale reactors and showed immediate benefit to microbial growth,” said Brian Jacobson, associate director of strategic operation at the Integrated Bioprocessing Research Laboratory (IBRL) at the University of Illinois Urbana-Champaign. “While there have been significant advances in synthetic biology resulting in a tremendous number of new products capable of being made through fermentation, we have seen very little innovation in the fermentation process or equipment to assist in scaling these discoveries. This technology has the potential to positively impact the economics of new products in a wide range of industries and can also be applied to existing processes or retrofit last generation fermentation equipment currently unsuitable for these new products."

Paul Gadbut, CEO of Hydrosome Labs, called the use of ultrafine bubbles as “a win for manufacturers, consumers and investors alike.”